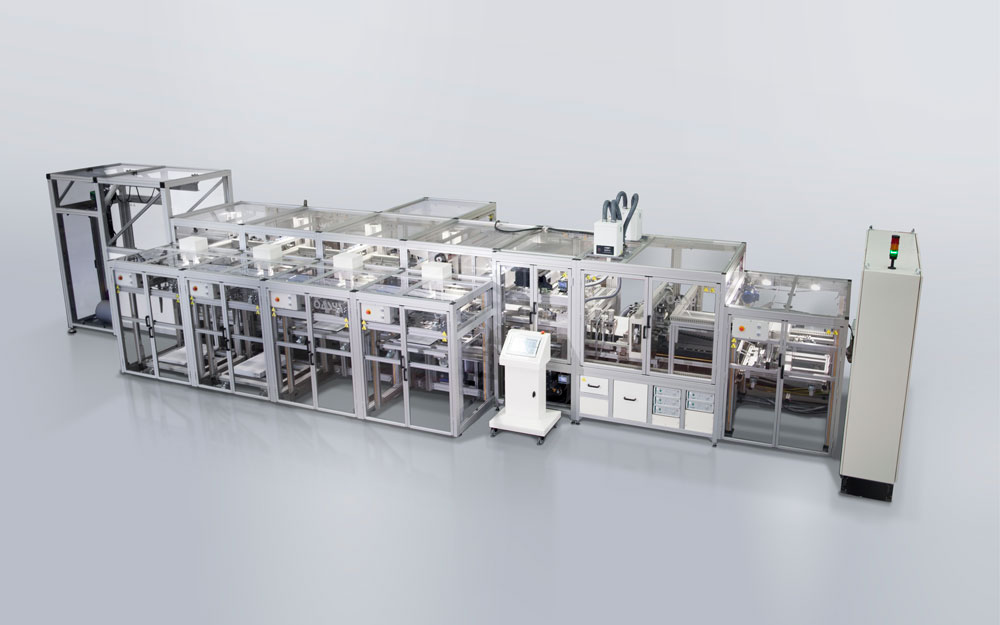

OHP200 REGISTRATION HOLE PUNCH

The OHP is a manually fed print registration hole punch for printed card sheet layers prior to Collation. Registered holes and slots are punched into the individual card sheet layers using printed sensor marks. This allows accurate manual collation by locating the holes over Collation pins on the OHC150 hand collator.

Individual card sheets are presented manually to datum pins on the bed of the OHP200 and holes / slots punched in alignment to the print by registering against printed sensor marks. The registration holes then align accurately in X Y and Theta with the printing on each sheet.

As the printed sensor marks are in the same position ( relative to the printing ) on each sheet the holes are consistently positioned and the layers then accurately align at Collation when placed over the pins on the OHC150

The OHP200 can use printed marks for punch alignment and now options are available to register directly from RFID antenna, foils and holograms – subject to testing.

Product Specification

- Precision of punching tolerances +/- 0.15mm to print

- Manual sheet feeding with automated servo controlled sheet registration.

- Individual sheet processing speeds of up to 400 sheets per hour, (depending upon sheet thickness)

- Processing thicknesses of 0.1mm – 0.5mm (Other sizes available on request)

- Flexibility of processing a variety of materials, eg. PVC, ABS, PETG etc. Other material types and any form of material type combinations are subject to testing and approval at Oasys.

Overview video

Click video above to see a working demonstration of the machine in action.

KEY FACTORS

COMPACT

FOOTPRINT

We understand that factory space can be at a premium. The Oasys machines are designed to have the maximum output per square foot of floorspace of any machine in their class.

LOW COST OF OWNERSHIP

Value for money is the focus achieved through maximum uptime, fast changeovers and minimal stoppage time. Limited maintenance based on proven design with built in diagnostics and remote support. This gives the optimal cost per card produced over the lifetime of the machine.

QUALITY CONSTRUCTION

All Oasys production machines are designed and built with quality in mind.From the frame construction to the use of the best custom configured sensors and the robust operational software.Oasys machines are often run 24/6 in the field and are built to enable this – 35 years of experience says that a higher build cost gives the customer a better performance and a faster return on investment.

FLEXIBLE OPERATION

The machines are designed to process all the major types of cards from Banking through Gift cards to high security ID. The machines will be configured to customer card sheet format and tooling made to match the materials and outputs required. Formats and configurations of build and processing can be altered automatically to predetermined settings with easy switching of tooling and load unload facilities.

SUPPORT AND SPARES

Internet based access to machines enables remote support to be provided – allowing diagnosis and intervention to resolve any issues quickly.

CONFIDENCE

As Specialists in a rapidly evolving industry Oasysprovides a machine that is able to process the latest in materials, components and construction.

Clients have the confidence that the Oasys technology is the best value for in technology, flexibility, and productivity money can buy.