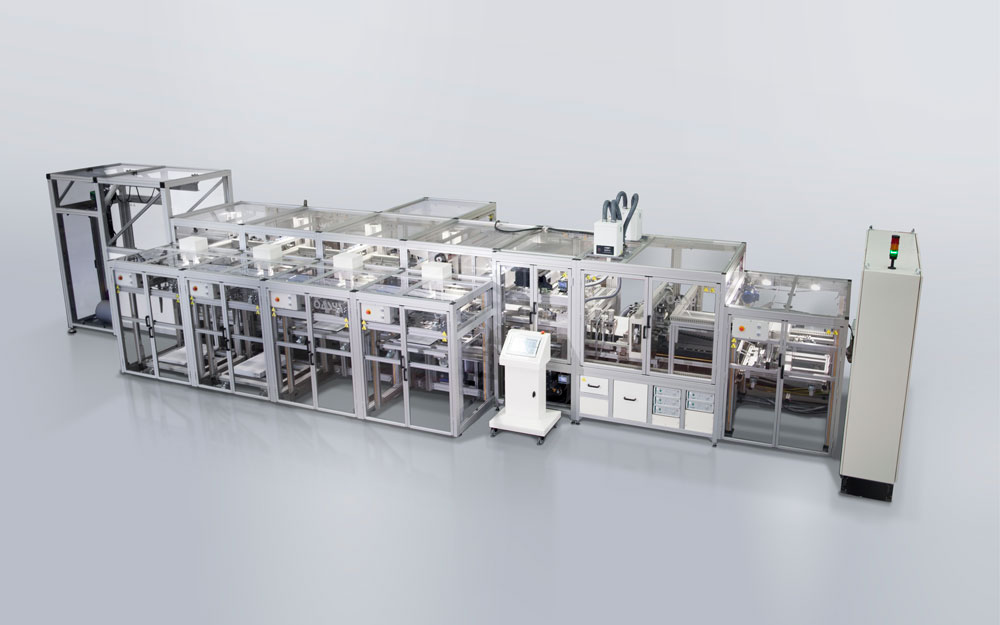

OCL450H Hand Feed Semi-Automatic Collator

The increasing complexity of some card structures and layers and the need for higher yields accuracy and output have made the Oasys Collator the machine of choice for professional Card manufacture across the industry.

Find out more about our range of Collators or ask us to recommend the best solution for your requirements.

Product Specification

The latest collation machine from Oasys, model OCL450H, has the key advantages of having a compact footprint and a competitive price. This model incorporates the best in practice, from a collation point of view, in that the magnetic stripe overlay is fully in-line guided to print, ultrasonic welding features are utilised as a standard feature and a double blade rotary trim process is utilised to ensure that overlay is consistently trimmed to match the core sheet footprint.

The OCL450H has been developed in response to the demand for high speed semi-automated collation of core and overlay, to create “card sheet sets” ready for the card lamination stage with the ability to easily vary the number of core sheets in the collation set.

The OCL450H combines web fed overlay, with or without magnetic stripe, and combines this with pre-printed core sheets to form between three, four or five layer card sheet sets. Higher substrate layers can be discussed if required.

The system therefore automates the collation processes between printing and lamination.

The OCL range is unique in the following way:

- Enables precise mag stripe overlay location to printed core sheets to be achieved.

- Handles thin gauge overlay down to 40 microns in thickness.

- Retains a high degree of flexibility, with the ability to handle different card formats and numbers of layers in one machine.

- A high speed collation process by one operator can be achieved, typically 450 sheets per hour.

- Ultrasonic welding features

- Double blade rotary trim facility

Overview video

Click video above to see a working demonstration of the machine in action.

KEY FACTORS

COMPACT

FOOTPRINT

We understand that factory space can be at a premium. The Oasys machines are designed to have the maximum output per square foot of floorspace of any machine in their class.

LOW COST OF OWNERSHIP

Value for money is the focus achieved through maximum uptime, fast changeovers and minimal stoppage time. Limited maintenance based on proven design with built in diagnostics and remote support. This gives the optimal cost per card produced over the lifetime of the machine.

QUALITY CONSTRUCTION

All Oasys production machines are designed and built with quality in mind.From the frame construction to the use of the best custom configured sensors and the robust operational software.Oasys machines are often run 24/6 in the field and are built to enable this – 35 years of experience says that a higher build cost gives the customer a better performance and a faster return on investment.

FLEXIBLE OPERATION

The machines are designed to process all the major types of cards from Banking through Gift cards to high security ID. The machines will be configured to customer card sheet format and tooling made to match the materials and outputs required. Formats and configurations of build and processing can be altered automatically to predetermined settings with easy switching of tooling and load unload facilities.

SUPPORT AND SPARES

Internet based access to machines enables remote support to be provided – allowing diagnosis and intervention to resolve any issues quickly.

CONFIDENCE

As Specialists in a rapidly evolving industry Oasysprovides a machine that is able to process the latest in materials, components and construction.

Clients have the confidence that the Oasys technology is the best value for in technology, flexibility, and productivity money can buy.