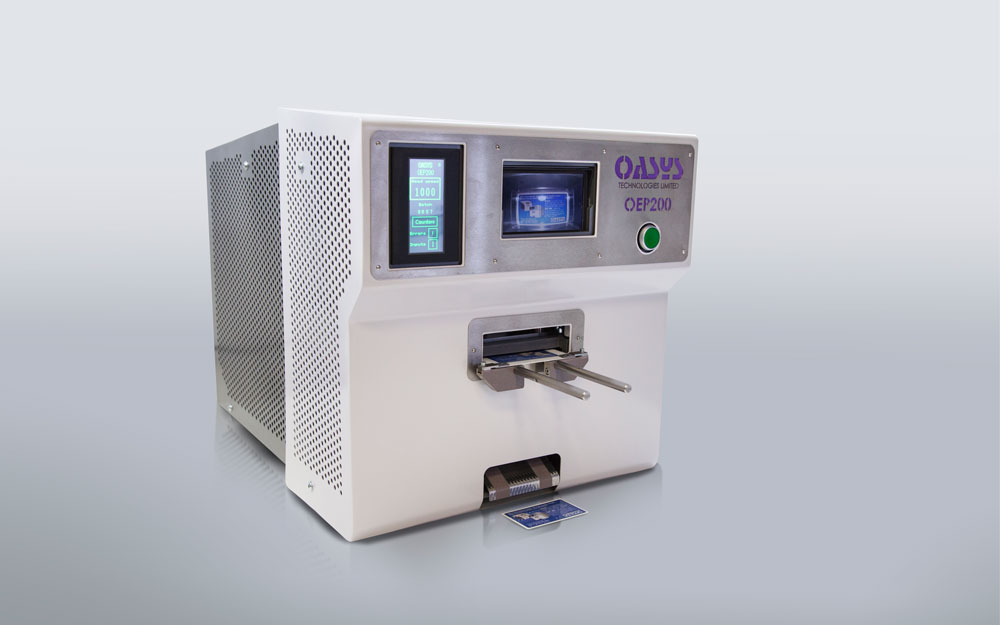

SDE Electric Die Cutting Machine

Oasys Technologies provide a full range of small-scale production equipment which can also be used for R&D and sampling.

The SDE series machines cut Teslin™or PVC every time with a clean edge.

Robust construction to cut plastic credit cards laminated I-D cards, computer cards, luggage tags, coaster mats and many more. The SDE electrically powered model gives effortless cutting via a 240V 50Hz motor and wrap spring clutch release. Operated by an air foot switch.

The cutting components (punch and die) are made from hardened and ground tool steel offering many thousands of cuts without the need to re-sharpen.

Interchangeable punches and dies can be ordered for these machines.

Guide bars can be set to your specific width of strip.

To cut Teslin™ the machine needs to be fitted with a single insert punch and die, this can be strip feed or set for single cards.

For ease of alignment, the die has sprung ball catches to lightly grip the card as well as sighting holes for printers marks.

Find out more about our range of small-scale card and ID production or ask us to recommend the best solution for your requirements.

Product Specification

- 1-UP Electric Punch Unit

- Applications – Bank, ID Cards, Contactless Cards

- Guaranteed ISO standard ‘Bank Card Quality

- Pressure switch activated

Overview video

Click video above to see a working demonstration of the machine in action.

KEY FACTORS

COMPACT

FOOTPRINT

We understand that factory space can be at a premium. The Oasys machines are designed to have the maximum output per square foot of floorspace of any machine in their class.

LOW COST OF OWNERSHIP

Value for money is the focus achieved through maximum uptime, fast changeovers and minimal stoppage time. Limited maintenance based on proven design with built in diagnostics and remote support. This gives the optimal cost per card produced over the lifetime of the machine.

QUALITY CONSTRUCTION

All Oasys production machines are designed and built with quality in mind.From the frame construction to the use of the best custom configured sensors and the robust operational software. Oasys machines are often run 24/6 in the field and are built to enable this – 35 years of experience says that a higher build cost gives the customer a better performance and a faster return on investment.

FLEXIBLE OPERATION

The machines are designed to process all the major types of cards from Banking through Gift cards to high security ID. The machines will be configured to customer card sheet format and tooling made to match the materials and outputs required. Formats and configurations of build and processing can be altered automatically to predetermined settings with easy switching of tooling and load unload facilities.

SUPPORT AND SPARES

Internet based access to machines enables remote support to be provided – allowing diagnosis and intervention to resolve any issues quickly.

CONFIDENCE

As Specialists in a rapidly evolving industry Oasysprovides a machine that is able to process the latest in materials, components and construction.

Clients have the confidence that the Oasys technology is the best value for in technology, flexibility, and productivity money can buy.