OCP400R High Speed Punch With Auto Card Boxing System

Oasys has for some years been the leader in high volume / large format ISO / Credit card punching – designing and building machines up to “11up” ( 11 cards at a time ) – at speeds of 60,000 cards per hour and processing up to 121 cards per sheet

This suits many of Oasys larger clients who require high volume for Banking and Commercial Cards and the ability to turn on capacity at short notice and respond quickly to their client needs

The high output creates need for more handling – cards at 60k per hour from the machine requires normally at least two operators. The continuing increase in labour costs – particularly in the last few years has driven demand for more automation

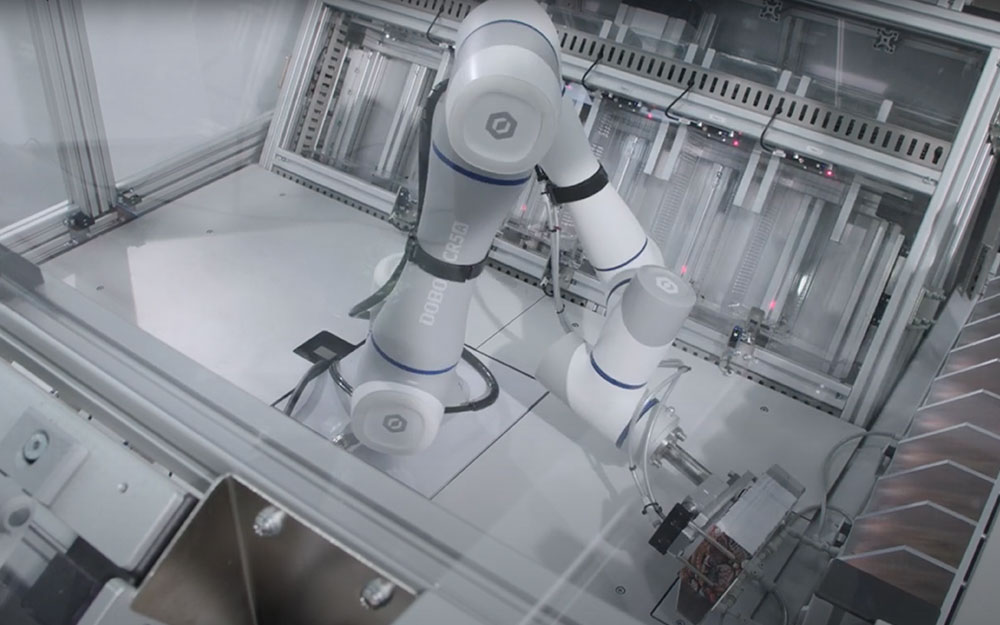

In response Oasys has created a card cutting /punching system with a fully automatic card handling and boxing unit – integrating an industrial Robot – the OCP440 R

This provides Sheet -to- Box in one single machine system taking printed ( paper ) or laminated plastic card sheets – processing into precision cut cards and boxed ( typically 500 per box ) at up to 60,000 cards per hour. Options are available for in process card counting

Product Specification

- Complete automation of card cutting from sheet loading to card output

- Processing of sheets direct from lamination to cut stacked cards without intermediate steps

- The ability to independently adjust each individual punching step throughout the sheet punching process.

- Cutting speeds of up to 60,000 cards per hour subject to sheet size.

- Processing thicknesses of 0.3mm – 1.5mm (see technical specification for details )

- Flexibility of processing a variety of materials, e.g. PVC, ABS, PETG etc.

- Precision cutting tolerances to +/- 0.1mm to better than 95%

- Optional guillotine facility for larger format processing

- Combination printing process capability ( multiple print jobs on one sheet )

- Optional card stacking into magazine facility

- Optional Auto Boxing – Roboxer card boxing

Overview video

Click video above to see a working demonstration of the machine in action.

Auto Card Boxing System – The Roboxer

Due to increased demand for automation Oasys developed in 2023 an Automatic Card boxing system – the Roboxer

Integrated at the exit of the 400 series Card Punch the Roboxer takes stacked cards from the punch and automatically boxes them –

In high speed card cutting this saves significant handling and labour and allows operator focus to remain on machine management and optimisation.

Product Profile

- Boxing speed up the 80,000 cards per hour – so boxing never becomes a bottleneck

- Loading normally 500 cards per box – other options available

- Loading into plastic or cardboard boxes

- Card thicknesses from 0,3 – 0,8mm thickness

- Materials include PVC, Paper, PETG, PC

- Option of card counting within the process ( subject to speed adjustment )

- Option of auto camera card inspection prior to boxing

In response to increasing demand for increased automation – reduced handling and labour saving, Oasys now offer AMR handling on many of their Credit ID Card and Passport Page production machines.

The machines can be loaded and unloaded automatically with materials being selected, verified and tracked via 2D barcode into and through the machine process.

This has the effect of improving traceability, reducing errors and allowing more comprehensive management of the individual processes and overall factory management system.

A range of AMR solutions is offered and further details available from Oasys on request.

KEY FACTORS

QUALITY CONSTRUCTION

All Oasys production machines are designed and built with quality in mind.From the frame construction to the use of the best custom configured sensors and the robust operational software.Oasys machines are often run 24/6 in the field and are built to enable this – 35 years of experience says that a higher build cost gives the customer a better performance and a faster return on investment.

FLEXIBLE OPERATION

The machines are designed to process all the major types of cards from Banking through Gift cards to high security ID. The machines will be configured to customer card sheet format and tooling made to match the materials and outputs required. Formats and configurations of build and processing can be altered automatically to predetermined settings with easy switching of tooling and load unload facilities.

SUPPORT AND SPARES

Internet based access to machines enables remote support to be provided – allowing diagnosis and intervention to resolve any issues quickly.

CONFIDENCE

As Specialists in a rapidly evolving industry Oasysprovides a machine that is able to process the latest in materials, components and construction.

Clients have the confidence that the Oasys technology is the best value for in technology, flexibility, and productivity money can buy.