Demand for optimum capacity and yield has driven the need to ensure material as clean as possible during assembly and manufacture of Credit Cards, ID Cards, and Passport Pages.

80% of manufacturing “scrap” is incurred in the first three steps of printing, collation and lamination and dust contamination is a major cause of this.

The polymers layer used in structure of the cards and ID documents are after polycarbonate and polyester etc. are particularly prone to static, which attracts dust and contamination causing the problem waste.

Keeping components clean and defect free during manufacturing contributes to the quality of the end product.

In manufacturing, for processes that use thin layers or foils as part of the structure it is often critical that these surfaces must be clean prior to final assembly or processing.

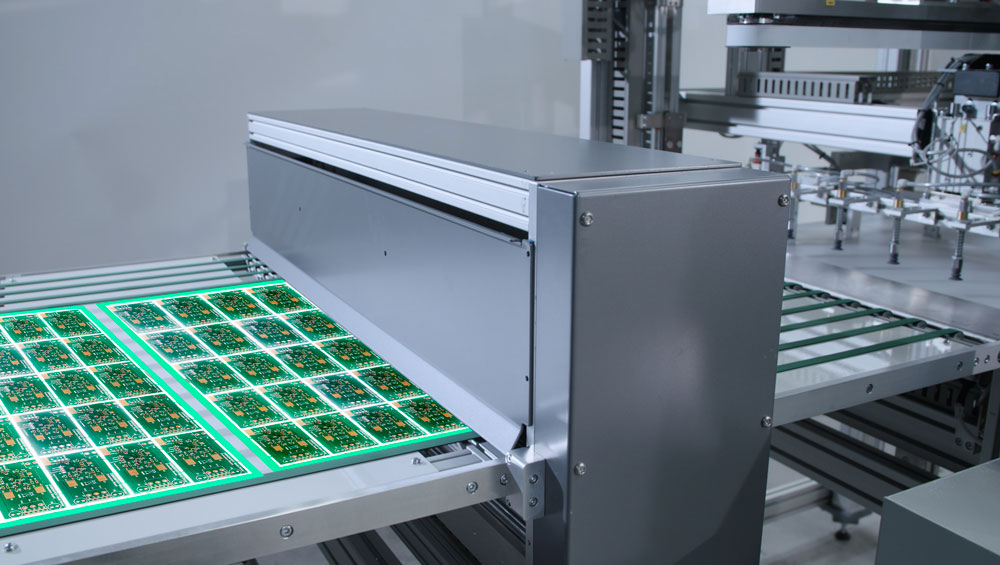

Examples include multilayer circuit boards ( PCBs) – where dust can cause electrical defects – Electronics such as display screens, and printed products such as Credit or ID cards where contamination can cause a visual defect.

Inline contact cleaning can ensure the layers or sheets that make up these products are clean and defect free immediately prior to processing and can remove over 98% of all dust and particles automatically from both sides and at the same time control static.

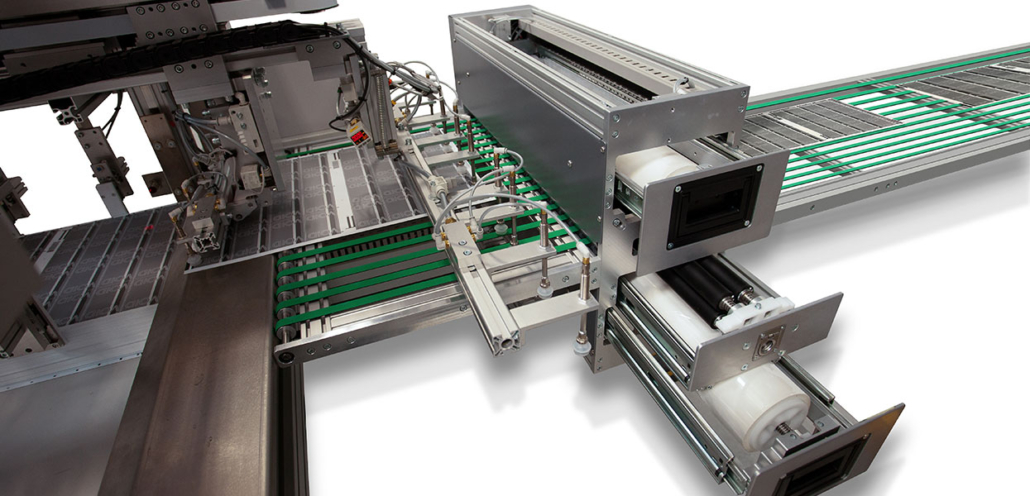

Systems can be integrated into existing processes or operate offline to prep material for subsequent processing.

CONTACT SHEET CLEANING

Contact cleaning is ideal for cleaning flat products in sheet or web form which can have dust contamination or fibres on the surface

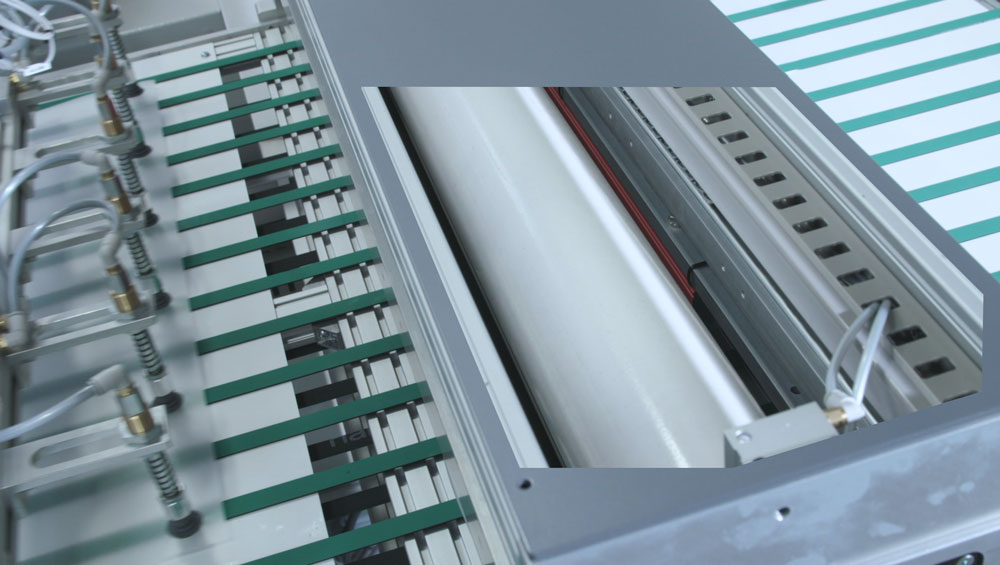

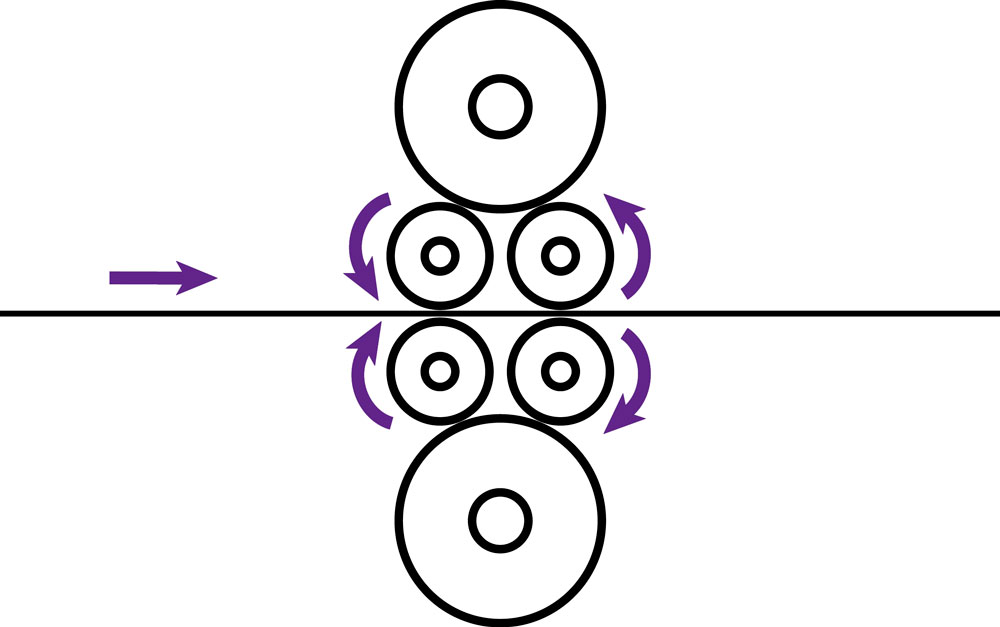

The elastomer roller has intimate contact with the product surface and removes particles – in addition it is engineered to neutralise and mitigate static charge on the product surface facilitating the removal of particles, dust and fibres.

Contamination that is picked up by the elastomer roller surface is then transferred to a sticky “Collection” roller which retains the dirt, dust and particles – thus keeping the elastomer roller clean and able to pick up further contamination.

The process of pick up and transfer to collection rollers is continuous and double sided – as the diagram below illustrates.

CONTACT BOARD CLEANING

Multilayer circuit boards ( multilayer PCBs) can have upwards of 20 layers of sophisticated circuitry buried inside – during manufacture each of these layers is sensitive to dust and contamination. It is essential therefore these complex electronic layers are kept contamination and defect free prior to and during the manufacturing processes.

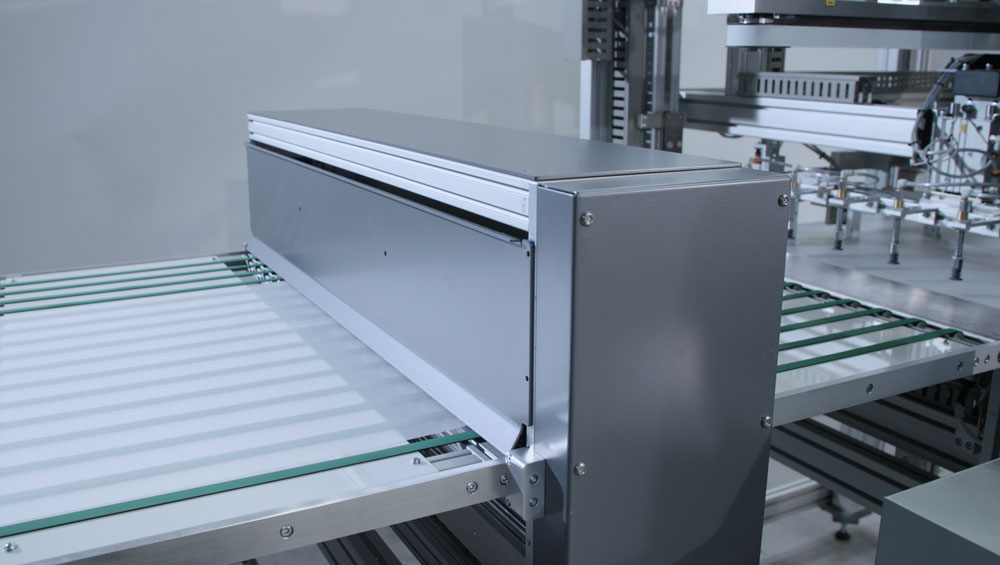

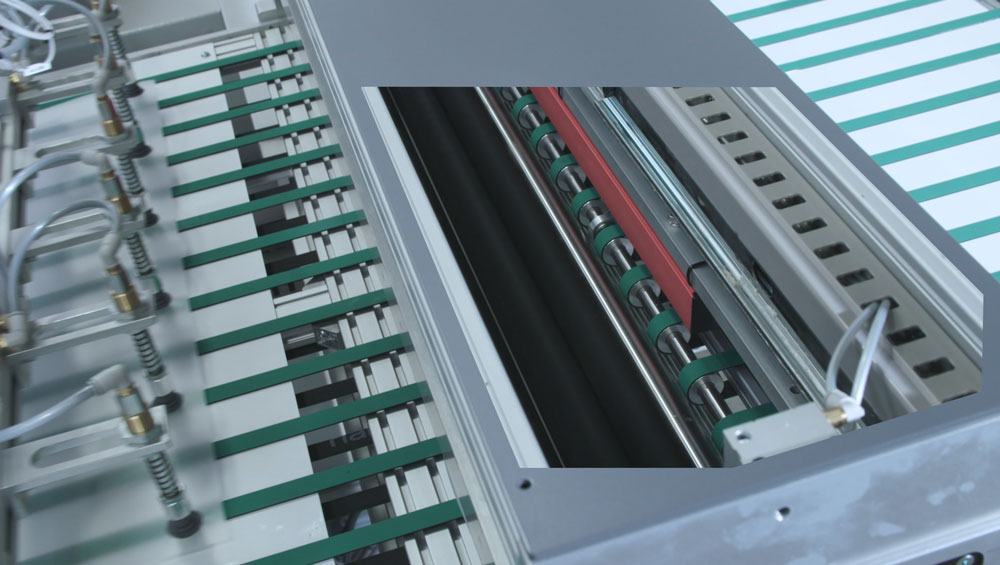

The OCC1000 contact sheet cleaner is designed to clean sheet surfaces using a mechanism that gently removes over 98% of all surface particles in a gentle but thorough process. Using a double sided automatic contact cleaning process the OCC1000 will lift particles, dust and fibres from the surface while controlling and mitigating any static that may be present.

Systems can be integrated into manufacturing processes or or configured as stand alone “offline” units to prepare defect free material ready for processing

TECHNOLOGY

Certain engineered elastomers are able to remove particles from a surface by an intimate rolling contact – this can clean surfaces and create effectively defect free products for onward assembly and manufacture – essentially increasing yields in production.

The technology of the elastomer roller can pick up particles below one micron and remove over 98% of dust, particles and fibre on a given surface.

Static can be an issue particularly on electronic and printed flat surfaces where dust and contamination attracts contamination due to electrically charged surfaces. The technology of the roller has built in anti static properties to control and mitigate static – allowing the contamination to be removed and reducing static charge in the product.

The technology is completed by a dirt “collection” system that cleans the elastomer roller – ensuring that particles to not get retransferred to the product surface.

PROCESS

Contact cleaning is ideal for cleaning flat products in sheet or web form which can have dust contamination or fibres on the surface

The elastomer roller has intimate contact with the product surface and removes particles – in addition it is engineered to neutralise and mitigate static charge on the product surface facilitating the removal of particles, dust and fibres.

Contamination that is picked up by the elastomer roller surface is then transferred to a sticky “Collection” roller which retains the dirt, dust and particles – thus keeping the elastomer roller clean and able to pick up further contamination.

The process of pick up and transfer to collection rollers is continuous and double sided

The sticky collection roller has removable layers – so that the sticky collection surface can be renewed regularly.

SYSTEMS

OCC1000 CLEANER

Demand for optimum capacity and yield has driven the need to ensure material as clean as possible during assembly and manufacture of Credit Cards, ID Cards, and Passport Pages.

80% of manufacturing “scrap” is incurred in the first three steps of printing, collation and lamination and dust contamination is a major cause of this.

The polymers layer used in structure of the cards and ID documents are after polycarbonate and polyester etc. are particularly prone to static, which attracts dust and contamination causing the problem waste.

For further information please contact our sales team

or call +44 (0) 1767 600232