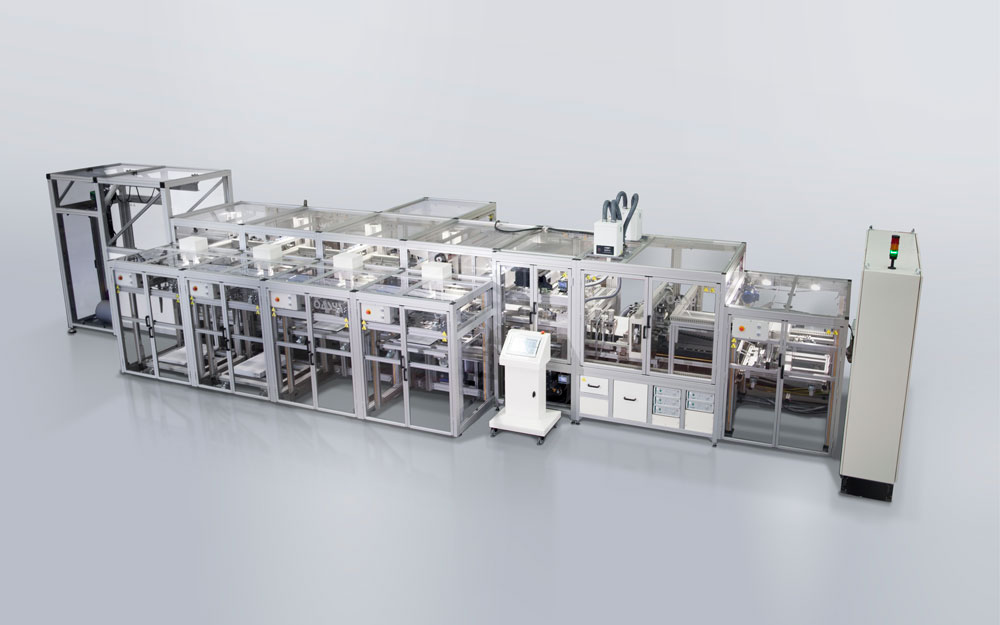

ASSEMBLY / COLLATION

The OCL 500RR and 600RR are state of the art models which handle an register and weld recycled and reclaimed plastics.

Product Specification

- Combines web fed overlay, with pre-printed core sheets to form between three to six layer card sheet sets.

- Unique precision, print to print core alignment eliminates edge to edge registration.

- Completely automates the processes between printing and lamination.

- Handles Recycled and Reclaimed ( RR) polymers – with registration system to overcome dimensional variability and maintain accuracy of assembly

- Ability to handle different card formats in one machine.

- *Will process recycled and reclaimed polymers, blends and composites including HDPE, PETGAG.

- Available as single core, two or three station unit.

- Options for contactless wire, etched or printed “inlay” processing – five layer sets.

- Proven industry track record.

LAMINATION

The OMTS and TS range of laminators having the pressure and temperature profile abilities to enable effective lamination of a range of reclaimed polymer blends.

Product Specification

- Proven track record for high quality lamination of all major Banking and D cards and eID Passport Pages

- Enhanced specifically for the lamination of high quality contactless products and Recycled and Reclaimed plastics

- *Capability to laminate Recycled and Reclaimed polymers, blends and composites including HDPE. PETGAG and PLA..

- Rigid four pillar construction with unique 4 cylinder self levelling hydraulics

- Thermally efficient lightweight alloy platens – with precision ramped heating and cooling profiles

- Multi stage hydraulic pressure application including “kiss” pressure facility

PUNCHING / CUTTING

Reclaimed and recycled polymers are more variable in quality and require different cutting geometries and more flexible cutting parameters to cope with this. Oasys OCP 400RR range of Card Punches enables a far wider range of cutting capabilities than a standard machine.

Product Specification

- Complete automation from sheet loading to CR80 ISO standard card output

- Independent adjustment of each individual punching step throughout the sheet punching process to overcome dimensional variation and optimise cut accuracy

- Cutting speeds in excess of 50,000 cards per hour subject to sheet size.

- Unique Control system with segmented adjustment of all cutting parameters during the cutting cycle and tooling configured and designed for Recycled and Reclaimed polymers blends and composites.

- *Flexibility of processing a variety of Reclaimed and Recycled materials including HDPE. PETGAG and PLA blends and composites.

- Precision cutting tolerances to +/- 0.1mm to better than 95%

- Optional guillotine facility for larger format processing

- Optional card sorting / stacking facilities

Note:

Performance is subject to the specific polymers blend and or composites used and subject to test and verification – the above information is a guideline and cannot be interpreted as a guarantee of performance on any specific material – customers are responsible to ensure the suitability for application under their specific conditions